608-831-0025 (International)

800-261-4446 (U.S.)

Workflow

Category

The Solution for Beam and Machine Verification

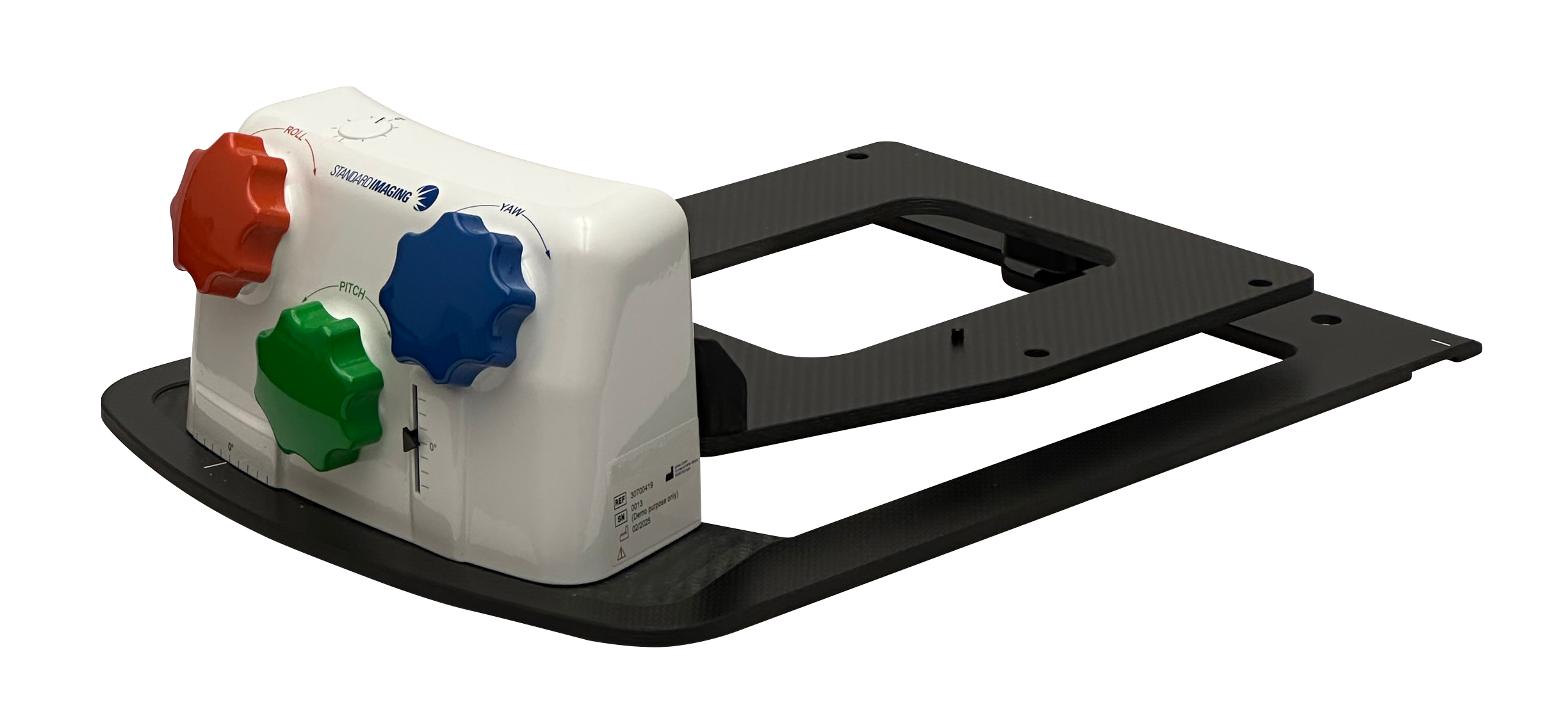

Optimized Detector Positioning For Key Linac QA Routine

453 air-vented pixel ionization chambers with optimized 5 mm spacing allows for accurate machine QA including dosimetric, mechanical, gating and MLC performance testing. Parallel readout from independent electrometers allows for fast measurements.

Water Phantom Free

Compare results to water phantom baselines and achieve accuracy within 0.5%. Perform accurate monthly machine QA without the hassle of a water phantom.

Fast Reports

Automatically compares energy measurements with their corresponding reference values. Test reports are created according to user-defined tolerances, and include reference values, allowing you to easily identify changes in your machine.

Download the QA CrossChecker Brochure

Specifications

| Hardware General Requirements | |

|---|---|

| Warm-up time | 15 min for relative; 60 min for absolute |

| Pre-irradiation | According Pre-irradiation |

| Cooling | Forced air cooling via two fans |

| Uniformity correction | Via an individual factory calibration matrix, determined with 60Co radiation, stored in the device |

| Hardware General Specification Data | |

| Application | Routine QA of high energy photon and electron beams |

| Positioning | Gantry mount (holder optional) or patient table |

| Measuring Quantity | Absorbed dose, dose rate |

| Energy Range | 60Co, 4 MV-30 MV Photon; 4 MeV-21 MeV Electron |

| Intrinsic build-up | 3 mm Tecaran ABS, density 1.06 g/cm³ |

| Backscatter material | RW3, thickness 22 mm |

| Dose rate range | 0.02-20 Gy/min |

| Signal to noise ratio | Less than 1 % with 1 cGy integrated dose |

| Dose linearity | Tested to be better than 0.5 % from 10 cGy to 5 Gy integral dose and better than 0.5 % from 0.1 Gy/min up to 4 Gy/min dose rate |

| Output factor | Within 1 % from 5 x 5 to 25 cm field size compared to CC13 between 6 and 18 MV |

| Outer Dimensions | 56 cm (L) x 6 cm (H) x 32 cm (W) |

| Weight | ~10 kg |

| Power Supply | ~10 kg |

| Power Supply | 100-240 V |

| Frequency | 50/60 Hz |

| Power Cord, Plug | US or German power plug included |

| Interface to PC | Point To Point or network Ethernet connection |

Resources

Webinars and Videos

Publications

- Independent Secondary Dose Calculation for Patient-Specific Quality Assurance: Quantitative Benefit of Monte–Carlo and Custom Beam Modeling

- Routine Machine Quality Assurance Tests for a Self Shielded Gyroscopic Radiosurgery System

- Feasibility Study Using HDR 1000+ Well-Type Ionization Chambers

- Feasibility Study Using HDR 1000+ Well-Type Ionization Chambers

- Whats New ESTRO 2025

- Transforming Radiation Therapy: Standard Imaging's Adaptivo In Vivo EPID Dosimetry Solution for Personalized Treatment Precision--A Comprehensive Clinical Use Case Review

- Evaluation of the Exradin A19 Ion Chamber for Reference Dosimetry in Megavoltage Photon Beams

- Evaluation of a Water-proof, Homogeneous Farmer-Type Ion Chamber for Orthovoltage and High Energy X-Rays and Electron Beams

- Commissioning and Cross-Comparison of Four Scanning Water Tanks

- Validation of the Acuros XB dose calculation algorithm versus Monte Carlo for clinical treatment plans

We Are Here to Help

Your Wisconsin Rep is

Here to Help

Change Location

Contact Us

Online Chat

We encourage you to contact our customer service and support team.

Customer Care

For best service, login to your account.